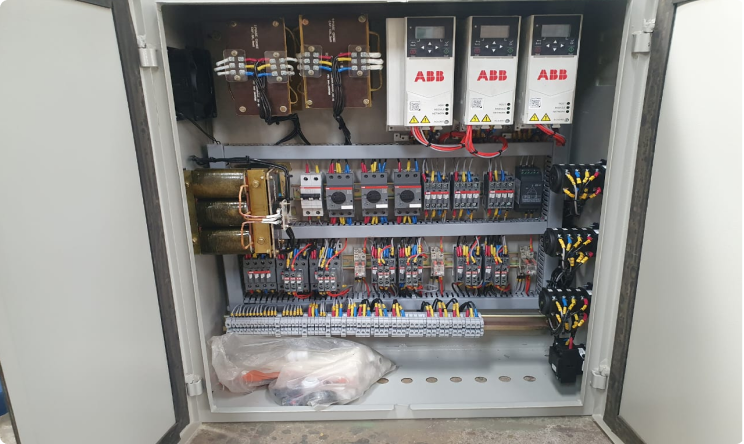

Control Panel

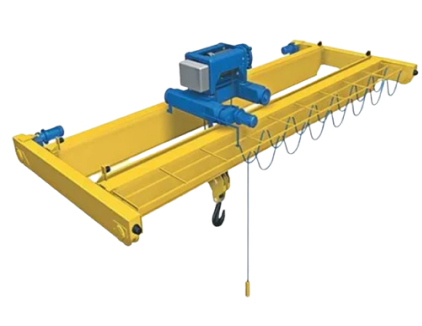

Custom Build Panel

EOT cranes with custom-built panels offer unique controls, safety features, and monitoring requirements for effective material handling..

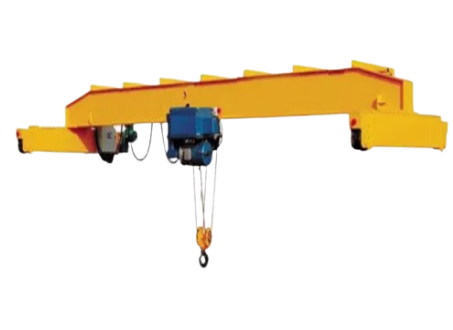

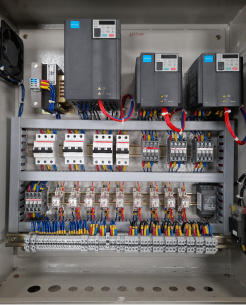

Eot Crane Control

The management of crane operations, including hoisting, trolley movement, and safety features, via an EOT (Electric Overhead Traveling) crane control panel, ensures accurate and secure material handling.

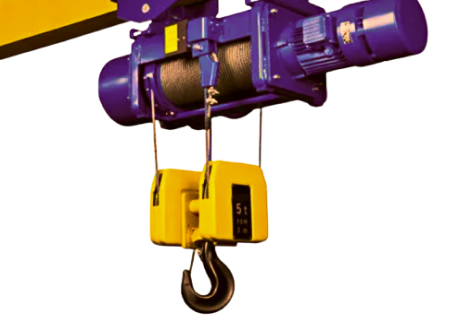

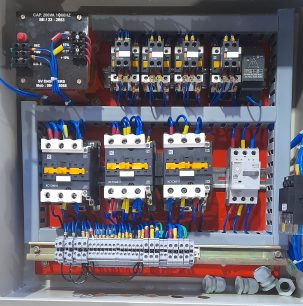

Goods Lift Panel

In order to facilitate effective material transport in industrial settings and to guarantee safety, dependability, and precise cargo handling, EOT cranes have goods lift panels that

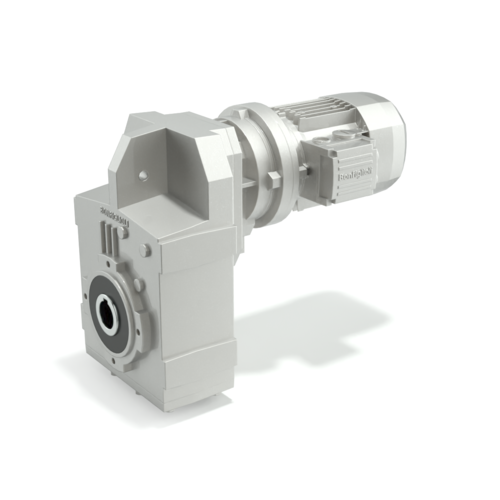

Plc Control Panel

The automated and accurate crane operations made possible by PLC (Programmable Logic Controller) control panels in EOT cranes increase safety, efficiency, and flexibility for a variety of industrial applications.